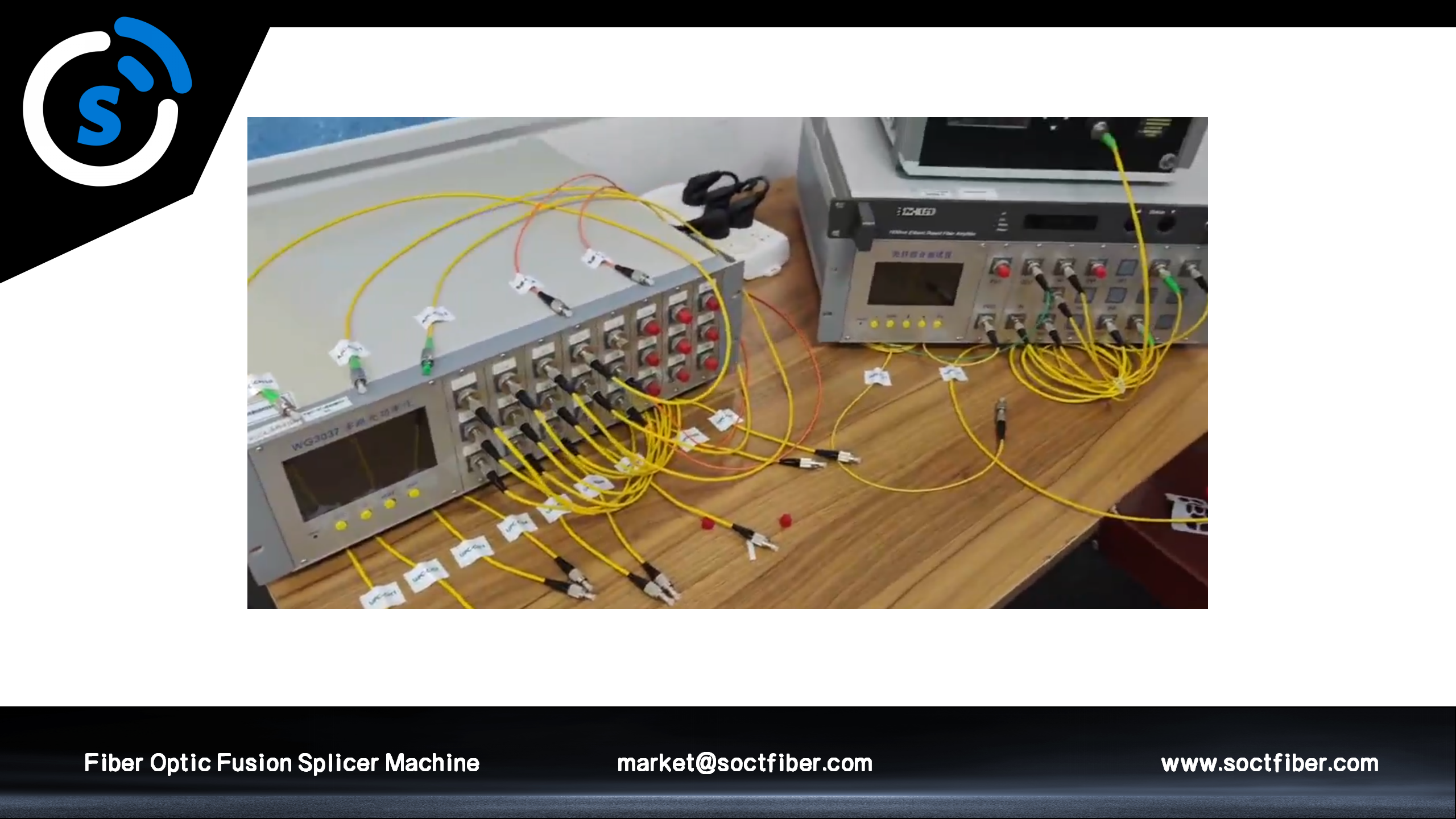

fiber optic fusion splicer tool

Fiber optic fusion splicer tool is an advanced piece of equipment intended to join two or more optical fibers by using melting and fusing methods. It features two main functions, high precision fiber splicing aiming at minimal signal loss and an extended connection that is highly durable and can resist environmental factors. The tool is packed with many technology features including an advanced heating system, live-image displays for exact alignment, as well the intuitive user interface as a touch screen. It is found widely in telecommunications systems, and be widely seen in the the great networks cable TV just to name a few others. It can be used for installation or maintenance of these facilities.