Introduction: Understanding Direct Buried Cables

Direct buried cables play a vital role in ensuring reliable power distribution for a variety of applications. Designed for installation directly underground without additional conduits, these cables offer many advantages, including cost-effective solutions and aesthetically pleasing installations. Proper installation is essential for maximizing the longevity and efficiency of direct buried cables, which withstand harsh environmental conditions. Failing to adhere to proper installation techniques poses a significant risk, potentially causing cable failures and safety hazards.

What is Direct Buried Cable and Why Proper Installation Matters

Direct buried cables are specialized electrical cables suitable for underground installation without protective conduits. This setup is especially beneficial for outdoor lighting, garden installations, and remote structure powering due to its durability and resistance to environmental elements. Proper installation ensures safety, compliance with regulations, and minimizes outages, which is crucial considering that 30% of cable failures can be attributed to improper installation, according to industry reports.

Choosing the right insulation—such as XHHW, USE, and UF ratings—is crucial for adapting cables to specific environmental conditions. These insulation materials offer varying degrees of protection against moisture, temperature fluctuations, and other external factors. Understanding these choices will help ensure that the installations are safe and durable. In conclusion, adopting best installation practices minimizes potential costly repairs and adheres to local codes, thus maintaining high standards and operational efficiency.

Choosing the Right Direct Burial Cable: Features for Outdoor Use

Key Characteristics for Direct Buried Cables

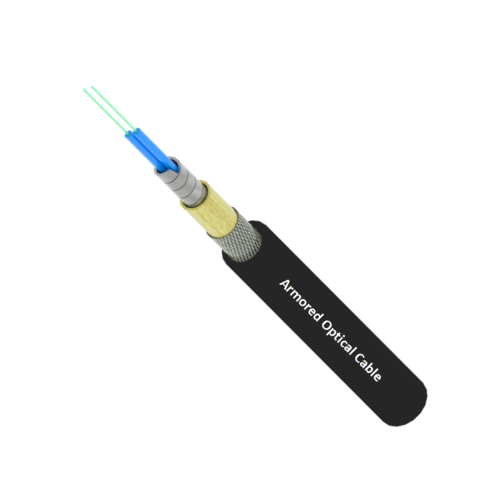

Direct burial cables are designed to withstand the harsh conditions they encounter underground. They must be made from materials that effectively resist moisture, UV radiation, and temperature fluctuations to ensure a long lifespan. It's essential to look for cables that meet the National Electrical Code (NEC) standards, which guarantee safety and efficiency. Additionally, taking into account the cable gauge and ampacity rating helps ensure that your power supply is sufficient while maintaining safety under load conditions. By adhering to these key characteristics, you can select a cable that is well-suited to your outdoor power needs.

Waterproofing Options in Direct Burial Cable Installation

When installing direct burial cables, selecting the right waterproofing solution is crucial for long-term performance. Options such as water-blocking gel and moisture-resistant jackets are designed to prevent water ingress, which could otherwise lead to cable degradation. The choice depends on the specific soil and environmental conditions of the area, especially in regions prone to flooding. Recent studies highlight that cables with advanced waterproofing capabilities can endure prolonged exposure to moisture without compromising their integrity, ensuring that your power systems remain safe and reliable.

Trenching and Burial Depth: Ensuring Proper Direct Buried Cable Installation

Preparing the Trench for Safety and Efficiency

Preparing the trench for direct buried cable installation requires careful consideration of safety and efficiency. First and foremost, it's crucial to adhere to local code requirements, which typically mandate a trench depth of about 24 inches for direct buried cables. This ensures protection from accidental damage due to surface activities such as gardening or landscaping. Additionally, trench width should be adequate to comfortably lay the cable and allow for future maintenance without stressing the cable. Employing safety practices—such as marking existing utility lines and using appropriate trenching equipment—significantly reduces risks during installation. For example, using tools that can map underground utilities helps prevent unwanted interference with existing infrastructures, fostering a safer installation experience.

Meeting Burial Depth Requirements for Protection

Meeting burial depth requirements is vital for the protective installation of direct buried cables. These depths are determined by factors including the cable type and intended usage, with some cables necessitating deeper placements than others. Regular inspections, coupled with strict adherence to installation guidelines, play a pivotal role in minimizing risks linked to changing environmental conditions and potential accidental damage post-installation. According to electrical safety organizations, not adhering to prescribed depths can lead to material failures and costly legal consequences. Therefore, understanding these guidelines ensures the longevity and reliability of the cable system while avoiding potential pitfalls. Regular check-ups and evaluations are imperative to address any depth-related concerns promptly.

Protection from Environmental Factors in Direct Buried Cable Installation

Shielding from Moisture and Water Ingress

Safeguarding direct buried cables from moisture and water ingress is crucial to prevent electrical malfunctions. Utilizing moisture-retardant materials in cable design greatly diminishes the risk of water-related failures. For instance, many cables now incorporate robust waterproof jackets specifically engineered to repel moisture and chemicals found in soil. Studies reveal that a significant number of cable failures stem from inadequate moisture protection during installation. Therefore, conducting regular maintenance checks can ensure the soil conditions surrounding the cables remain optimal, which enhances their longevity and performance.

Managing Temperature Extremes and Soil Conditions

To maintain functionality in diverse climates, it is essential to select cables rated for a broader temperature range. This consideration becomes particularly important for long-term installations, where temperature fluctuations can impact the integrity of cable insulation over time. Soil composition and conditions, including frost lines, should also be factored into the selection of cable type and burial methods. Expert analyses emphasize that temperature extremes can degrade cable insulation, making the choice of insulation significant to mitigate such risks. Consequently, proper cable selection and installation practices can ensure the durability and efficiency of direct buried cables in various environmental conditions.

Testing After Installation: Verifying Proper Direct Buried Cable Functionality

Essential Post-Installation Testing Procedures

Post-installation testing is crucial in ensuring the functionality and safety of direct buried cables. Conducting insulation resistance tests helps verify that cables remain uncompromised during installation. The recommended resistance values will vary depending on the cable type, but the essential factor is the cables' capability to resist electrical leakage. Additionally, continuity testing serves as a means to check the integrity of electrical pathways, confirming that the setup meets operational standards. Industry protocols advocate for routine testing of newly installed systems. These routine tests aim to identify early-stage faults, allowing immediate mitigation of potential risks associated with cable installations.

Troubleshooting Common Direct Burial Cable Issues

Encountering problems with direct burial cables, such as shorts from moisture ingress or physical damage, is not uncommon. Systematic testing often reveals these issues, providing a basis for effective troubleshooting. Environmental factors can also lead to cabling degradation, which necessitates a well-defined troubleshooting protocol to rectify failures promptly. Utilizing professional diagnostic tools and services can streamline the troubleshooting process, effectively reducing downtime and minimizing repair expenses. These advanced tools empower technicians to diagnose cable faults with precision, enhancing the overall maintenance and longevity of the buried cable system.

Conclusion: Essential Tips for Successful Direct Buried Cable Installation

Successfully installing direct burial cables demands adherence to certain critical principles. Key takeaways include maintaining appropriate trenching depths as per local codes, choosing the right materials, and implementing regular maintenance schedules to extend the lifespan of your installation. Staying informed about advancements in cable technology and evolving installation techniques can significantly enhance performance and reliability. Furthermore, investing time in meticulous planning ensures a robust foundation for operational success, particularly in industrial and residential settings. By following these guidelines and embracing continuous learning, we can not only safeguard the integrity of our projects but also promote a more efficient and effective underground cabling system.

FAQ Section

What are direct buried cables?

Direct buried cables are electrical cables designed for underground installation without the need for protective conduits, ideal for outdoor lighting and remote powering.

Why is proper installation of direct buried cables important?

Proper installation is crucial to ensure safety and compliance with regulations, and to minimize outages and cable failures which can result from incorrect installation.

What considerations should be made when choosing direct burial cables?

Consider the insulation ratings, material durability against environmental elements, and compliance with National Electrical Code (NEC) standards.

Why is trench depth important for direct buried cable installation?

Trench depth is essential to protect the cables from surface activities and ensure long-term safety and efficiency.

How can environmental factors affect direct buried cables?

Moisture, temperature extremes, and soil conditions can degrade cable insulation, impacting performance over time.

What testing procedures are recommended post-installation?

Insulation resistance tests and continuity testing are essential to confirm cable integrity and operational standards.

Table of Contents

- Introduction: Understanding Direct Buried Cables

- What is Direct Buried Cable and Why Proper Installation Matters

- Choosing the Right Direct Burial Cable: Features for Outdoor Use

- Trenching and Burial Depth: Ensuring Proper Direct Buried Cable Installation

- Protection from Environmental Factors in Direct Buried Cable Installation

- Testing After Installation: Verifying Proper Direct Buried Cable Functionality

- Conclusion: Essential Tips for Successful Direct Buried Cable Installation

-

FAQ Section

- What are direct buried cables?

- Why is proper installation of direct buried cables important?

- What considerations should be made when choosing direct burial cables?

- Why is trench depth important for direct buried cable installation?

- How can environmental factors affect direct buried cables?

- What testing procedures are recommended post-installation?