Rozumienie Kabli Optycznych Wewnętrznych

Kluczowe komponenty i struktura

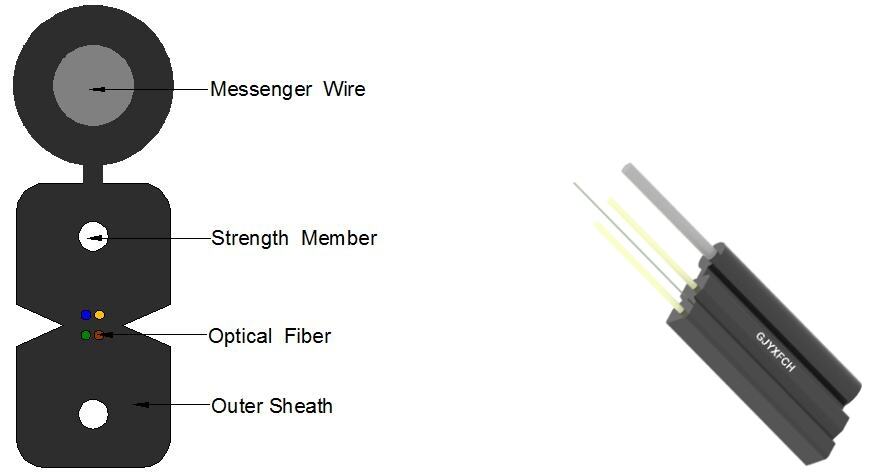

Wewnętrzny kable światłowodowe są kluczowe dla zapewnienia wydajnej i szybkiej transmisji danych. Składają się przede wszystkim z trzech podstawowych elementów: rdzenia, otoczki i ochronnego warstwienia zewnętrznego. Rdzeń, często wykonany z szkła lub plastiku, jest zaprojektowany do umożliwienia szybkiego przenoszenia danych, będąc ścieżką dla sygnałów świetlnych. Otaczająca rdzeń otoczka odzwierciedla światło z powrotem do rdzenia, co pozwala zachować integralność sygnału. Razem te elementy zapewniają, że sygnały świetlne są przechowywane bez zniekształceń, czyniąc z kabli optycznych niezawodny wybór w różnych zastosowaniach, w tym łącze internetowego i zarządzania danymi.

Jednomodowe kontra wielomodowe włókna

Wybór między światłowodami jednomodowymi a wielomodowymi może istotnie wpłynąć na wydajność sieci, odległość i koszt. Światłowody jednomodowe pozwalają tylko na propagację jednego trybu światła, co sprawia, że są idealne do komunikacji na długie odległości ze względu na zmniejszoną dyspersję modalną. W przeciwieństwie do nich, światłowody wielomodowe są lepiej przystosowane do krótszych odległości, takich jak w centrach danych, ponieważ wspierają wiele trybów światła, co może prowadzić do zwiększonej prędkości, ale są ograniczone pod względem zasięgu. Choć kabele jednomodowe często wiążą się z wyższym kosztem, ich zdolność do efektywnego pokonywania większych dystansów czyni je preferowanym rozwiązaniem dla rozległej infrastruktury sieciowej. Światłowody wielomodowe zaś oferują kosztowefektywne rozwiązanie w środowiskach, gdzie dominuje komunikacja na krótkie odległości.

Oceny kabel Plenum vs. Riser

Rozumienie różnicy między przewodami klasy plenum a riser jest kluczowe dla zapewnienia bezpiecznych instalacji zgodnych z normami budowlanymi. Przewody klasy plenum są konstruowane w taki sposób, aby minimalizować rozprzestrzenianie się dymu i płomieni, co czyni je odpowiednie do przestrzeni o dużym obiegu powietrza, takich jak kanały wentylacyjne i sufony. Ich skład obejmuje materiały opóźniające pożary, co zmniejsza ryzyko wydzielania się szkodliwych dymów podczas incydentów, takich jak pożar. Z drugiej strony, przewody klasy riser są projektowane do przestrzeni pionowych między piętrami, oferując wystarczający opór przed pożarem, mimo że mniej wytrzymały niż przewody klasy plenum. Wybór odpowiedniego przewodu obejmuje uwzględnienie zarówno zgodności z normami bezpieczeństwa, jak i konkretnych wymagań środowiska instalacji, co gwarantuje optymalną ochronę i funkcjonalność dla sieci fibrowo-optycznych.

Podstawowe Narzędzia i Materiały do Montażu

Kabel światłowodowy Nożyczki i ściągacze

Podczas instalacji kabli internetowych z optyczną fibrą posiadanie odpowiednich narzędzi jest kluczowe dla efektywności i precyzji. Nożyczki do cięcia kabel optycznych są specjalnie zaprojektowane, aby zapewnić dokładne cięcie, minimalizując wszelkie potencjalne uszkodzenia wrażliwych włókien. Ta precyzja jest kluczowa dla utrzymania integralności kabla optycznego. Ponadto, strippersy są niezbędne do usuwania zewnętrznej warstwy ochronnej kabla bez szkodzenia wewnętrznym włóknom. Inwestycja w wysokiej jakości nożyczki i strippersy to nie tylko rekomendacja, ale konieczność. Te narzędzia przyspieszają procesy instalacji i znacząco redukują błędy, prowadząc do płynniejszego połączenia internetowego i ogólnej niezawodności sieci.

Fusory i cleavery

Sprzęt do spawania światłowodowego, taki jak spawarki i nożyce do spawania, odgrywa kluczową rolę w procesie instalacji światłowodów. Spawarki są niezbędne do łączenia włókien z minimalną utratą sygnału, co jest podstawą wydajnych systemów światłowodowych kabli internetowych. Wydajne nożyce do spawania są równie ważne, ponieważ przygotowują końce włókien z precyzją, zapewniając czyste cięcia gotowe do spawania. Ta precyzja jest niezbędna, ponieważ bezpośrednio wpływa na wydajność całej sieci. Regularna konserwacja tych narzędzi jest niezbędna do zachowania ich wysokiej wydajności i wydłużenia ich żywotności, co ostatecznie wspiera trwałość sieci światłowodowych.

Urządzenia do testowania OTDR

Aby skutecznie utrzymywać i diagnozować sieci fiberoptyczne, przyrządy OTDR (Optical Time Domain Reflectometers) są nieocenione. Te narzędzia do testowania pomagają identyfikować usterki w sieciach fiberoptycznych, dostarczając kluczowe dane dotyczące długości, strat i lokalizacji problemów w kablowych. Systematyczne korzystanie z OTDR-ów może znacząco poprawić niezawodność sieci, szybko wykrywając i rozwiązując potencjalne problemy. To nie tylko zwiększa ogólną wydajność operacji konserwacyjnych, ale również gwarantuje, że systemy internetowe oparte na technologii fiberoptycznej działają na najwyższym poziomie, minimalizując czas przestoju i przerwy w usługach.

Proces instalacji krok po kroku

Planowanie tras kable'owych i kontrole bezpieczeństwa

Planowanie tras kabelowych i przeprowadzanie kontroli bezpieczeństwa mają kluczowe znaczenie w projektach instalacji światłowodów. Ten wstępny etap obejmuje staranne rozważania, aby zapobiec kosztownemu ponownemu routingu oraz zagwarantować zgodność z regulacjami dotyczącymi instalacji kabel światłowodowych. Dzięki szczegółowej ocenie barier fizycznych i istniejącej infrastruktury instalatorzy mogą skutecznie planować trasy kable. Ponadto, przeprowadzenie dokładnych kontroli bezpieczeństwa przed instalacją minimalizuje ryzyka i potencjalne zagrożenia, chroniąc zarówno sprzęt, jak i personel zaangażowany w proces. Ten proaktywny podejście gwarantuje nie tylko zgodność z przepisami, ale również pomyślne wdrożenie sieci światłowodowych.

Prawidłowe techniki ciągnięcia, aby uniknąć uszkodzeń

Użycie odpowiednich technik ciągnięcia jest kluczowe podczas instalacji kabla optycznego, aby uniknąć uszkodzeń i zapewnić optymalne wydajność. Użycie odpowiedniego napięcia podczas ciągnięcia jest niezbędne, aby zapobiec zbyt dużemu naprężeniu w włóknie, co mogłoby spowodować pęknięcia lub pogorszenie jakości sygnału. Wykorzystanie narzędzi takich jak smar do kabelców może ułatwić płynniejsze ciągnięcie poprzez zmniejszenie tarcia i ryzyka uszkodzeń podczas procesu instalacji. Ponadto, świadomość kątów instalacji i ich wpływu na integralność włókien jest istotna. Zapewnienie, że kable są ciągnięte z odpowiednim napięciem i kątem, może znacząco przyczynić się do dłuższej trwałości i niezawodności sieci optycznej.

Zakończenia i instalacja łączników

Zakończenie i instalacja łączników są kluczowymi fazami w procesie instalacji światłowodów, umożliwiającą bezszwowe łączenie sieci. Obejmuje to umiejętnie przyczepianie łączników do końców światłowodów, co zapewnia połączenia o niskich stratach, poprawiając ogólną wydajność sieci. Opanowanie technik związanych z zakonczeniem jest kluczowe dla utrzymania integralności światłowodów i dostarczania optymalnej jakości sygnału. Ponadto, wybór odpowiednich łączników wpływa nie tylko na efektywność bieżącej instalacji, ale również ma znaczenie dla przyszłego konserwowania i ulepszania sieci. Stawiając priorytet na właściwej instalacji łączników, można zagwarantować zarówno natychmiastową, jak i długoterminową skuteczność sieci.

Testowanie połączeń za pomocą źródeł światła

Testowanie połączeń fibry optycznej za pomocą źródeł światła jest niezwykle ważnym etapem procesu instalacji, umożliwiającym debugowanie i weryfikację przed ostatecznym wdrożeniem. Używanie źródeł światła pomaga zidentyfikować wszelkie straty połączeń lub problemy, co umożliwia ich szybkie korygowanie w celu zapewnienia optymalnej wydajności sieci. Przeprowadzając dokładne testy, instalatorzy mogą rozwiązać wszelkie potencjalne problemy na wczesnym etapie, uniemożliwiając przyszłe przerwy w świadczeniu usług. Ponadto, prowadzenie rejestru przeprowadzonych testów dostarcza cennej referencji dla przyszłych działań diagnozujących. Ten systematyczny podejście gwarantuje niezawodną i efektywną sieć fibry optycznej, gotową do wdrożenia i użytkowania.

Najlepsze praktyki dla optymalnej wydajności

Utrzymywanie minimalnego promienia zakrzywienia

Aby zapewnić optymalne wydajność podczas instalacji kabli woltowych, przestrzeganie minimalnego promienia zgięcia jest kluczowe. Dotrzymywanie tych specyfikacji uniemożliwia utratę sygnału i potencjalne złamanie włókna, co chroni integralność Twojej sieci. Dla instalacji w ciasnych przestrzeniach, stosowanie ochronnych rurociągów może pomóc w utrzymaniu wymaganych promieni zgięcia skutecznie. Zaleca się również regularne szkolenie dla instalatorów, aby upewnić się, że są oni kompetentni w rozumieniu i stosowaniu standardów promienia zgięcia, co minimalizuje błędy podczas instalacji.

Zarządzanie luźnymi fragmentami za pomocą pętli serwisowych

Efektywne zarządzanie luźnymi odcinkami jest kolejną najlepszą praktyką przy instalacji kabli fibry optycznej. Wprowadzenie pętli serwisowych zapewnia wystarczający luźny odcinek, aby móc dostosować się do przyszłych zmian w sieci bez powodowania większych zakłóceń. Ta metoda pomaga w utrzymaniu integralności sieci i zmniejsza nadmierną obciążenie kabli. W złożonych środowiskach można wykorzystać liny serwisowe do efektywnego zarządzania luźnymi odcinkami, co gwarantuje elastyczność i zrównoważony rozwój infrastruktury sieciowej.

Kodowanie kolorów dla łatwej identyfikacji

Użycie kodowania kolorami zwiększa wydajność instalacji kabli optycznych, umożliwiając łatwe ich identyfikowanie i zmniejszając czas konserwacji. Standardowy system kodowania kolorami jest kluczowy, ponieważ zapobiega niewłaściwym połączeniom i gwarantuje dokładność procesu instalacji. Szkolenie montażystów w zakresie tych kodów kolorystycznych może znacząco poprawić ogólną dokładność instalacji, pomagając w przyszłych zadaniach rozwiązywania problemów i konserwacji. Ta praktyka jest kluczowa do zarządzania rozległymi infrastrukturami sieciowymi z wieloma kablami optycznymi.

Przezwyciężanie typowych wyzwań związanych z instalacją

Zapobieganie utracie sygnału w ciasnych przestrzeniach

Zapobieganie utracie sygnału podczas instalacji światłowodowych jest kluczowe, zwłaszcza w ciasnych przestrzeniach, gdzie ostre zakręty mogą pogorszyć wydajność. Aby ograniczyć ten problem, efektywne planowanie odgrywa istotną rolę. Przez zaplanowanie ścieżki instalacji z góry i zidentyfikowanie potencjalnych punktów problematycznych możemy unikać zakrętów, które mogą zagrozić integralności sygnału. Używanie sprzętu specjalnie zaprojektowanego dla przestrzeni ograniczonych, takiego jak światłowody niewrażliwe na zakręty lub mikrokanały, jest również korzystne w minimalizowaniu ryzyk podczas instalacji. Dodatkowo, skupienie się na przepływie powietrza może zapobiec nagromadzeniu się ciepła, co mogłoby wpłynąć na wydajność szafy. Ten podejście gwarantuje, że infrastruktura pozostaje wydajna nawet przy ograniczeniach przestrzennych.

Rozwiązywanie Problemów Kompatybilności

Zgodność między łącznikami a urządzeniami jest podstawowa, aby uniknąć niepotrzebnych poprawek i utrzymać efektywny system fibry optycznej. Regularne sprawdzanie zgodności przed instalacją może pomóc w zidentyfikowaniu niezgodności i umożliwić szybkie rozwiązania. Równie ważne jest by być na bieżąco z nowymi trendami technologicznymi, aby upewnić się, że nowe instalacje płynnie integrują się z istniejącymi systemami. Przyjmując standardyzację komponentów sieciowych, dalszymi minimalizujemy potencjalne problemy w bardziej skomplikowanych konfiguracjach integracyjnych. Standardyzacja nie tylko usprawnia procesy, ale również zmniejsza prawdopodobieństwo przyszłych wyzwań operacyjnych.

Bezpieczne obsługa kruchych włókien szklanych

Obsługa wrażliwych włókien szklanych podczas instalacji światłowodowych wymaga specjalistycznego szkolenia, aby zapewnić zarówno bezpieczeństwo, jak i zmniejszyć ryzyko uszkodzeń. Osoby zaangażowane w procesy instalacji powinny przjść kompleksowe szkolenie w zakresie zarządzania włókniami i technik ich instalacji. Ponadto, stosowanie odpowiedniego wyposażenia ochronnego, takiego jak rękawice i okulary zabezpieczające, jest kluczowe do ochrony przed przypadkowymi uszkodzeniami. Wprowadzenie surowych protokołów dotyczących przechowywania i transportu włókien minimalizuje również ryzyko ich łamania lub uszkodzenia, co pozwala zachować integralność i długowieczność instalacji. Dzięki tym rozwiązaniom możemy zmniejszyć wyzwania związane z obsługą tych kruchych elementów.

Kabel światłowodowy Wskazówki dotyczące konserwacji

Regularne procedury inspekcji i czyszczenia

Regularne przeglądy i czyszczenie są kluczowe dla utrzymania wydajności kabla optycznego. Planując spójne przeglądy, możemy zidentyfikować potencjalne problemy, zanim eskalują w kosztowne kwestie. Ten proaktywny sposób obejmuje korzystanie ze specjalistycznych czyszczydeł zaprojektowanych specjalnie dla optyki, które pomagają zapobiec kontaminacji, która mogłaby pogorszyć jakość sygnału. Aby uprościć proces, trzeba prowadzić szczegółowy dziennik konserwacji. Ten dziennik ułatwia prowadzenie dokumentacji i zwiększa efektywność operacyjną, thanks do upewnienia się, że wszystkie poprzednie działania konserwacyjne są łatwo dostępne i zorganizowane.

Efektywne uaktualnianie systemów dziedziczonych

Efektywna modernizacja starszych systemów fibrowych wymaga strategicznego podejścia, które uwzględnia obecną wydajność i przewiduje przyszłe potrzeby. Faza planowania powinna obejmować szczegółową analizę istniejącej infrastruktury, aby upewnić się, że nowe komponenty są zgodne. Ten krok jest kluczowy, ponieważ determinuje sukces całego procesu ulepszeń. Ponadto, włączenie skalowalnych projektów do systemu może zminimalizować zakłócenia podczas przyszłych ulepszeń, umożliwiając płynniejsze przejścia w miarę postępu technologicznego. Ostatecznie, ten sposób działania gwarantuje, że sieć pozostaje mocna i elastyczna wobec nowych wymagań.

Dokumentowanie układów sieciowych

Dokładna dokumentacja układów sieciowych jest niezwykle cenną praktyką, która ułatwia rozwiązywanie problemów i przyszłe ulepszenia. Szczegółowe rekordy konfiguracji sieci pozwalają na szybszą diagnostykę i rozwiązywanie problemów, co może znacząco zmniejszyć czas simplyfikacji. Używanie narzędzi cyfrowych do mapowania sieci zwiększa dostępność tej informacji, czyniąc ją gotową do użytku wtedy, gdy jest potrzebna, i pomaga zmniejszyć błędy związane z ręczną dokumentacją. Poprzez utrzymywanie aktualnych rekordów upewniamy się, że układy sieciowe pozostają aktualne i przydatne, wspierając efektywne zarządzanie i rozwój infrastruktury fibry optycznej.

Sekcja FAQ

Jakie są główne składniki kabli fibry optycznej przeznaczonych do użytku wewnętrznego?

Kable fibry optycznej przeznaczone do użytku wewnętrznego składają się z rdzenia, osłonki i chroniącej warstwy zewnętrznej. Rdzeń umożliwia szybkie przenoszenie danych i jest otoczony osłonką, która gwarantuje integralność sygnału.

W jaki sposób różnią się/single-mode i multi-mode fibry?

Włókna jednomodowe pozwalają tylko na jeden tryb światła, są odpowiednie dla długich odległości, podczas gdy włókna wielomodowe wspierają kilka trybów, będąc idealne dla krótszych odległości i szybszych prędkości.

Jaka jest różnica między przewodami klasy plenum a klasy riser?

Przewody klasy plenum są ognioodporne i odpowiednie do zastosowania w obszarach o dużym obiegu powietrza, podczas gdy przewody klasy riser są projektowane do przestrzeni pionowych, oferując wystarczający opór wobec ognia.

Dlaczego utrzymanie minimalnego promienia zgięcia jest ważne w instalacjach fibrowo-optycznych?

Utrzymanie minimalnego promienia zgięcia zapobiega utracie sygnału i uszkodzeniu włókna, co jest kluczowe dla integralności i wydajności sieci.

Jaka jest rola testów OTDR w konserwacji fibryki optycznej?

Testy OTDR pomagają identyfikować usterki w sieciach fibrowych, dostarczając kluczowych danych na temat długości, straty i lokalizacji problemów, aby poprawić niezawodność sieci i zmniejszyć czas simplyfikacji.

Zawartość

- Rozumienie Kabli Optycznych Wewnętrznych

- Podstawowe Narzędzia i Materiały do Montażu

- Proces instalacji krok po kroku

- Najlepsze praktyki dla optymalnej wydajności

- Przezwyciężanie typowych wyzwań związanych z instalacją

- Kabel światłowodowy Wskazówki dotyczące konserwacji

-

Sekcja FAQ

- Jakie są główne składniki kabli fibry optycznej przeznaczonych do użytku wewnętrznego?

- W jaki sposób różnią się/single-mode i multi-mode fibry?

- Jaka jest różnica między przewodami klasy plenum a klasy riser?

- Dlaczego utrzymanie minimalnego promienia zgięcia jest ważne w instalacjach fibrowo-optycznych?

- Jaka jest rola testów OTDR w konserwacji fibryki optycznej?